Entering a Five-Digit code operates this Keypad Switch. Build it yourself using off-the-shelf components. Although it was designed to control a Burglar Alarm - it has other uses.

Introduction

The prototype of the Enhanced Alarm Keypad was built using only the Stripboard Layout as a guide. So - if you have faithfully reproduced that layout - you will have a working circuit.

Once you're satisfied that your layout is correct - and you have made a careful and thorough check of the underside of the board - it's time to power-up the circuit and test its operation. This is always an anxious moment. If you construct a lot of circuits - you might consider building the Current Limiting Power Supply - or alternatively - you could add the Simple Current Limiter to your existing PSU. Both will let you set an upper limit on the amount of current supplied to your circuit - and so protect it from any serious damage.

Setup

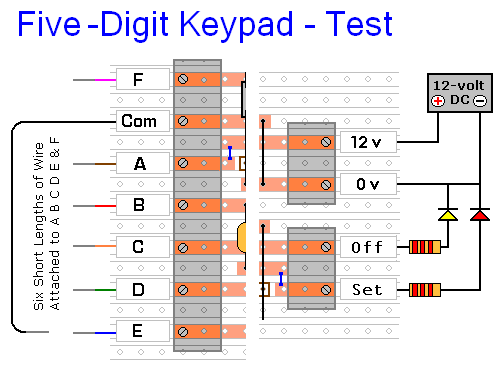

A couple of resistors and LEDs are all that's needed to demonstrate that the "Off" and "Set" outputs are working properly - and you can simulate the keypad-switches using short lengths of wire.

If You Find a Problem

If - in the course of the test - you find that something is not working properly - a careful inspection of the relevant area of the circuit board - should turn up the cause of the problem. Where you've cut the board to size - look for small loose strands of copper left behind by the saw. Check the board for short-circuits caused by component leads touching each other. If an LED is not lighting - check that it's connected the right way round. It can also happen that the stripboard itself is faulty. I have seen cases where the copper tracks have not been completely severed from one another during manufacture.

If you've built your circuit using the specified components - and you've followed the step-by-step construction guide described on the Five-Digit Keypad Support Page - then the chances are that any bug will be caused by something minor - a component connected the wrong way round - a missing or unwanted solder bridge - an incomplete cut in the track etc. If you haven't used the specified transistors - check the pin configuration. Just because the transistors look the same - do not assume that they have the same pin configuration.

If you can't see anything obvious - adopt a systematic approach to faultfinding. Simply replacing components at random is rarely successful. Begin by double-checking that all of the cuts in the tracks have been made - that they are all In The Right Place - and that they sever the track completely. Use a magnifying glass - and backlight the board. It only takes the smallest strand of copper to cause a problem.

When you're satisfied that the tracks have been severed in all the right places, check that you have made - and correctly placed - all 9 solder bridges. Check especially the bridge that connects pins 4 and 12 of the IC. Mark each bridge with a felt-tip pen - or something similar - so that it can be easily identified later.

Next, carefully examine the full length of each track. If you backlight the board - it makes potential problem areas easier to spot. Look for unwanted solder bridges. Your felt tip markings will tell you which ones should be there - and help you identify any that shouldn't be there.

If all else fails and you still haven't found the cause of the problem - work your way through the assembly instructions on the Support Page. Check each individual component and link - to make sure that it's present and correctly positioned.

Print out the drawings and mark off the components as you go. Pay particular attention to the orientation of the diodes - electrolytic capacitors and transistors. Make sure that Pin 1 of the IC is in the top left-hand corner - and that all of its pins are correctly inserted into the socket. Take your time and examine each individual component carefully.

Alternatively, you can take the following approach - suggested for those who have not used the stripboard layout.

If You Have Designed Your Own Layout

For faultfinding purposes you can think of the circuit in two distinct halves. There is the code input section that results in pin 10 and pin 11 going high - and the output section that causes the relay to energize and de-energize.

Try to get the output section working first. Start by connecting a length of wire to the "Com" terminal. Then disconnect the end of R7 that goes to pin 10 - and the end of R11 that goes to pin 11.

Turn-on the power and touch the "Common" lead to the free end of R11 - the relay should energize and remain energized. Next, touch the "Common" lead to the free end of R7 - the relay should de-energize and remain de-energized. In other words - by touching R11 and R7 with the "Common" lead - you should be able to energize and de-energize the relay.

Once the output section is working properly - turn off the power - and reconnect R11 and R7. Then check to see if your circuit's working. If it's not - examine the code entry section.

Turn-off the power and disconnect one side of R2. It doesn't matter which side. This will remove the limit on the time for entering the code.

Turn-on the power and - using a digital voltmeter - go through the code entry sequence. Make each of the following checks - in turn. If at any stage you do not get the correct readings - investigate.

- Briefly, touch "F" with the "Common" lead - to discharge C1.

- Check that pin 1 is low - that pin 2 is low - and that pin 3 is low.

- Touch "A" briefly with the "Common" lead. Check that this takes pin 1 high - and that it stays high.

- Touch "B" briefly with the "Common" lead. Check that this takes pin 2 high - and that it stays high.

- Check that pin 3 is now high. This means that gate 1 has functioned properly.

- Check that pin 5 is high, that pin 6 is low and that pin 4 is low.

- Touch "C" briefly with the "Common" lead. Check that this takes pin 6 high - and that it stays high.

- Check that pin 4 is now high. This means that gate 2 has functioned properly.

- Check that pin 12 is high, that pin 13 is low and that pin 11 is low.

- Touch "D" briefly with the "Common" lead. Check that this takes pin 13 high - and that it stays high.

- Check that pin 11 is now high. This means that gate 3 has functioned properly.

- Check that pin 8 is high, that pin 9 is low and that pin 10 is low.

- Touch "E" briefly with the "Common" lead. Check that this takes pin 9 high - and that it stays high.

- Check that pin 10 is now high. This means that gate 4 has functioned properly.

If pins 10 and 11 are high - and they remain high - the code entry sequence has been successful. Now that you have both the input and output sections working - reconnect R2. Then check that your circuit is functioning correctly - by using the procedure described at the Top of the Page .

SUGGESTIONS

SUGGESTIONS

SUGGESTIONS

SUGGESTIONS