This simple circuit will energize a relay at regular intervals. The length of the intervals is adjustable from seconds to days - and beyond.

Learn More About How A Cmos 4001 Monostable Works

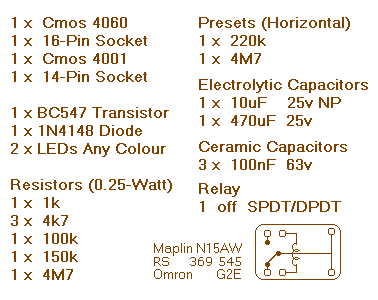

Parts List

|

|

|

|

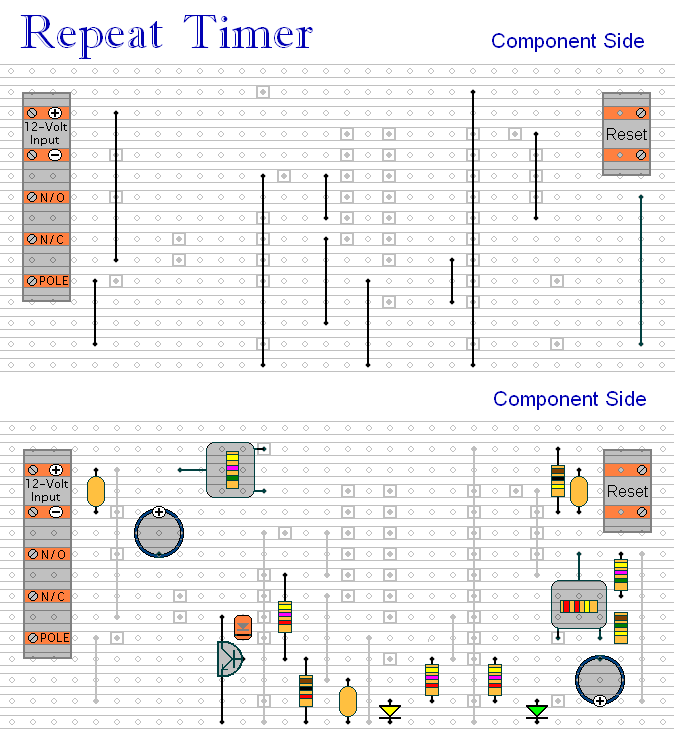

Construction Guide

Click here if you're new to constructing stripboard projects.

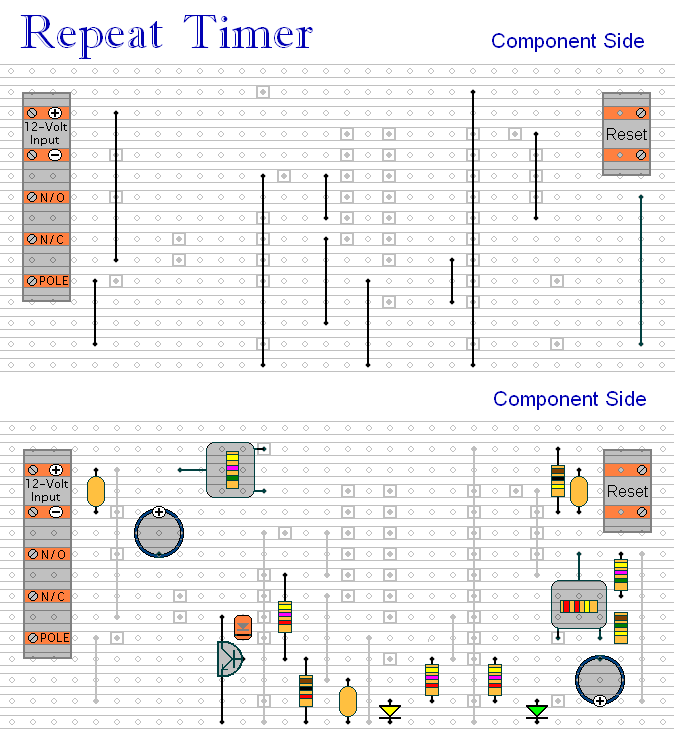

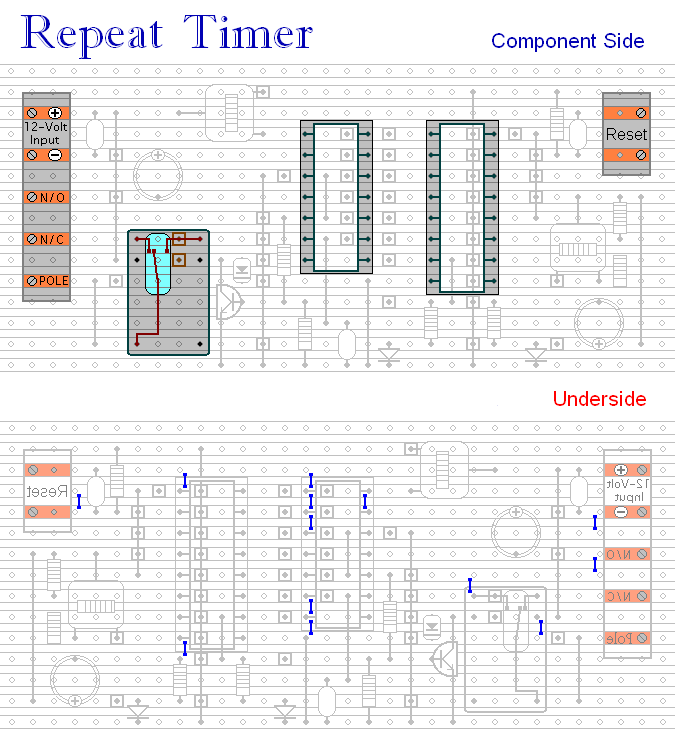

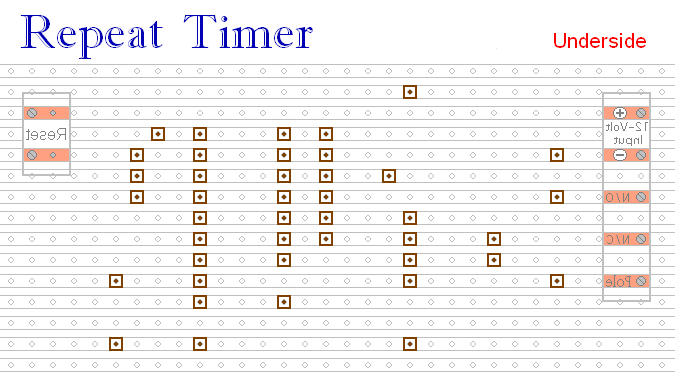

The prototype of the timer was built using only the Stripboard Layout as a guide. So - if you reproduce the layout - you will have a working timer. Details of how to Test Your Finished Circuit Board are also provided.

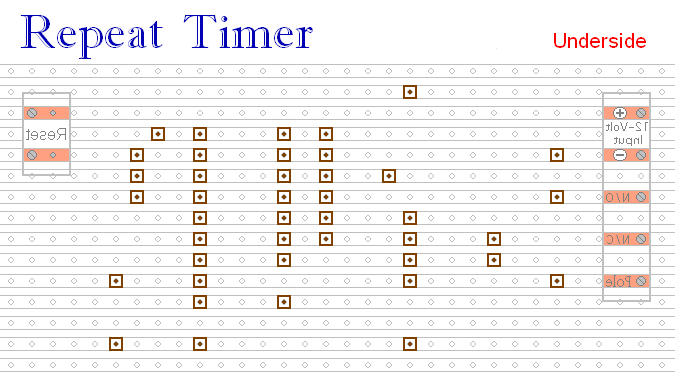

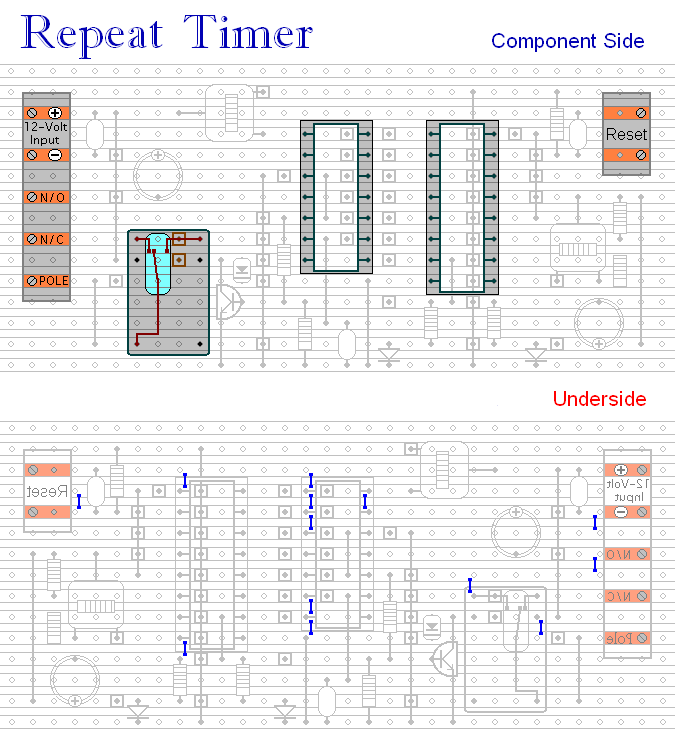

The terminals are a good set of reference points. To fit them - you may need to enlarge the holes slightly. Then turn the board over and use a felt-tip pen to mark the 42 places where the tracks are to be cut. Before you cut the tracks - use the "actual size" drawing to Check That The Pattern is Correctly Marked .

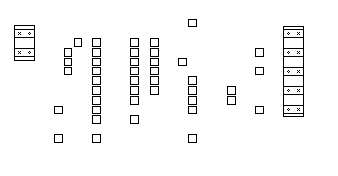

Actual Size

When you're satisfied that the pattern is right - cut the tracks. If you don't have the proper track-cutting tool - a 6 to 8mm drill-bit will do. Just use the drill-bit as a hand tool - there's no need for a drilling machine. Make sure that the copper strip is cut all the way through. Sometimes a small strand of copper remains at the side of the cut and this will cause malfunction. Use a magnifying glass - and backlight the board. It only takes the smallest strand of copper to cause a problem.

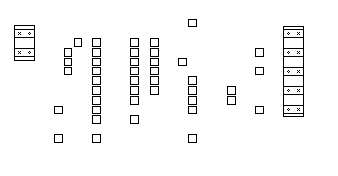

Next make and fit the Ten Wire Links. I used bare copper wire on the component side of the board. Telephone cable is suitable - the single stranded variety used indoors to wire telephone sockets. Stretching the core slightly will straighten it - and also allow the insulation to slip off.

Then fit the 7 resistors - the 2 presets - the 5 capacitors - the 2 LEDs - the transistor - and the diode. The resistors are all shown lying flat on the board - but those connected between close or adjacent tracks are actually mounted standing upright. The same is true for the diode.

Fit the relay and the two IC sockets. Then examine the underside of the board carefully - to make sure that there are no unwanted solder bridges or other connections between the tracks. If you backlight the board during the examination - it makes potential problem areas easier to spot. When you're satisfied that everything is in order - add the 13 solder bridges to the underside of the board.

Finally - insert the 4060 and 4001 into the sockets. In each case, make sure that pin 1 is in the top left-hand corner - and check carefully that all of the pins are correctly inserted into the socket. Sometimes - instead of entering the socket - a pin will curl up underneath the IC.

You Are Now Ready To Test Your Finished Circuit Board.

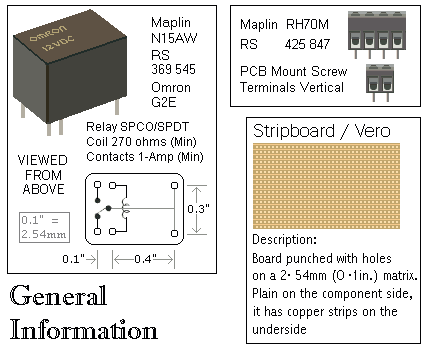

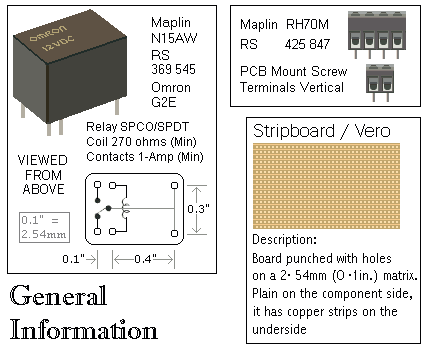

General Information

Click Here For A Photograph Of The Prototype.

SUGGESTIONS

SUGGESTIONS

SUGGESTIONS

SUGGESTIONS