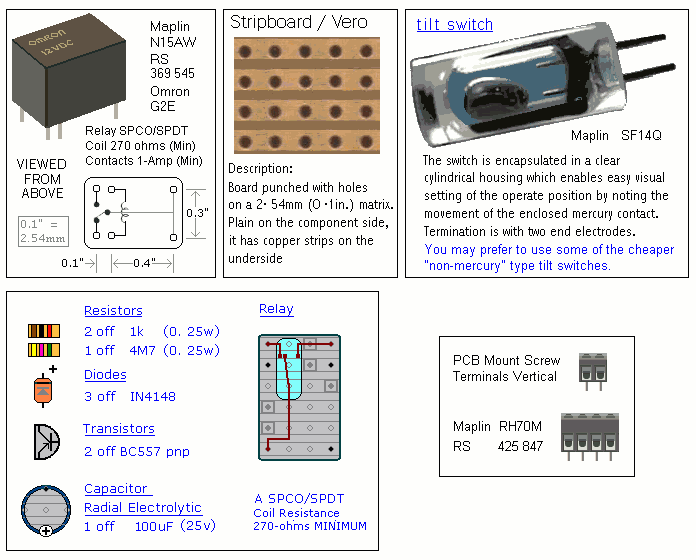

The components used in the circuit should be widely available. However, none of them are critical. So - if you can't find the specified parts -

You're certain to find something that will do just as well.

The alarm is intended primarily for use on a motorcycle. I didn't want the circuit to drain the motorcycle battery - so I designed it to have a very low standby current. This was achieved by using normally-open trigger switches. I also made sure that there are no purely resistive connections between the positive rail and ground.

On a modern motorcycle you will normally use a 12-volt relay and a 12-volt siren. But the circuit will work at 6-volts. So you can use it to protect your "Classic" machine. Just choose a relay and a siren suitable for the lower voltage.

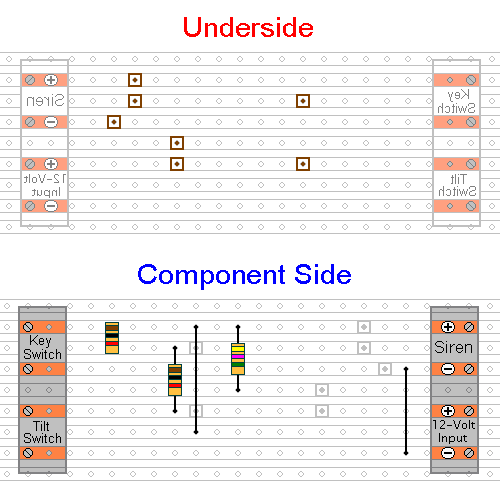

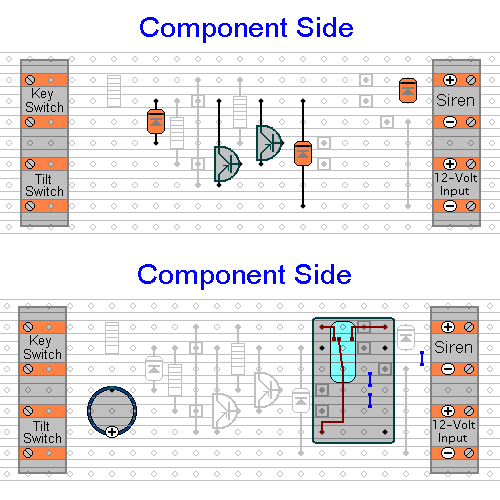

Stripboard or Veroboard is a board drilled with a matrix of 1mm holes spaced approximately 2.5 mm apart and joined in rows by copper strips. The piece required has 9 rows with 24 holes in each - and measures roughly 6 cm by 2.5 cm. (2.5 in by 1 in). The drawing shows the board with PCB mounting terminal blocks but - to save money and/or space - the wires may be soldered to veropins or directly to the board itself.

"Mercury Tilt Switches" are generally small glass bulbs with two contacts at one end. Inside the bulb is a "ball" of mercury. When the switch is "tilted" a few degrees off the horizontal - the mercury flows to one end and connects the contacts together.

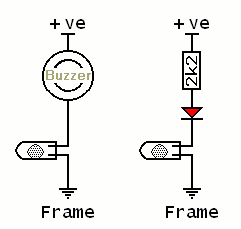

Mercury tilt switches are expensive. You may prefer to use the cheaper "non-mercury" type. The main difficulty with these is that - unlike mercury switches - you can't actually see what's happening inside. This can make them troublesome to position accurately. When setting-up the switching point, you may find it helpful to use a small buzzer - or an LED connected in series with a 2k2 resistor. Alternatively - you could

Add The LED Module to the alarm - and use it to help you position the switches.

Parts List

Click Here For A Photograph Of The Prototype.

Construction Notes

Click here if you're new to constructing stripboard projects.

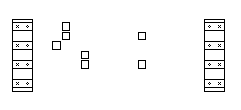

The terminals are a good set of reference points. To fit them - you may need to enlarge the holes slightly. Then turn the board over and use a felt-tip pen to mark the 9 places where the tracks are to be cut. Before you cut the tracks, use the "actual size" drawing to

Check That The Pattern is Correctly Marked .

Actual Size

When you're satisfied that the pattern is right - cut the tracks. Make sure that the copper is cut all the way through. Sometimes a small strand of copper remains at the side of the cut and this will cause malfunction. Use a magnifying glass - and backlight the board. It only takes the smallest strand of copper to cause a problem. If you don't have the proper track-cutting tool - a 6 to 8mm drill-bit will do. Just use the drill-bit as a hand tool - there's no need for a drilling machine.

Next fit the three resistors and the two links. I use a small piece of "Blu Tack" to hold the components and links in place temporarily - while I solder them to the board. A little putty or modelling clay should work equally as well.

The resistors are all shown lying flat on the board. However, R1 is mounted standing upright. For the two links, use the off-cuts of wire you've trimmed from the resistors. Then fit the 2 transistors and the 3 diodes. Again, D3 is mounted standing upright

Fit the capacitor and the relay. Pay particular attention to the orientation of the capacitor. Note that the positive terminal faces downwards.

Next - double check the position and orientation of all of the components. Then examine the board very carefully - to make sure that there are no unwanted solder bridges or other connections between the tracks. When you're satisfied that everything is in order - add the three solder bridges to the underside of the board.

You Are Now Ready To Test Your Alarm

Set Your Alarm Automatically

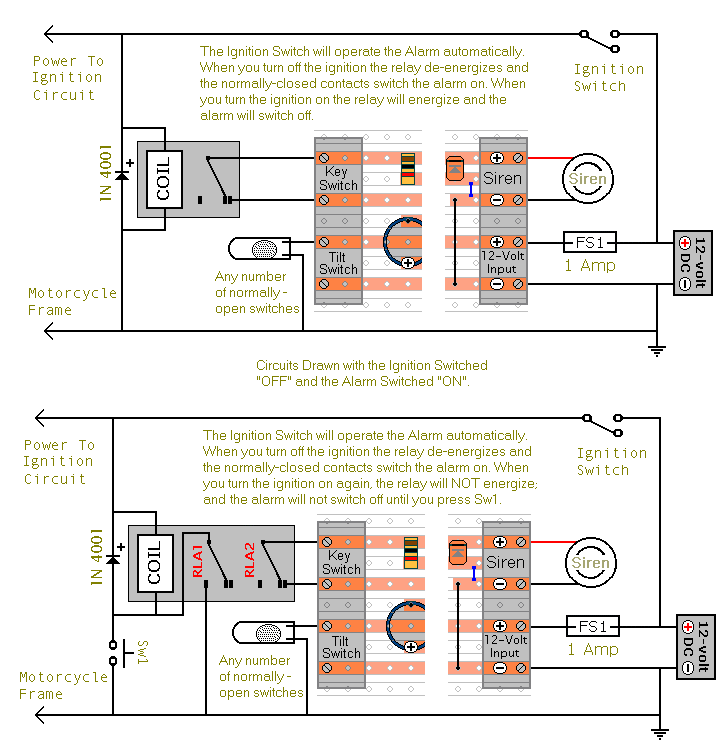

You can use a keyswitch or a hidden switch to operate the alarm; but add a small relay, and the alarm can be made to operate itself automatically. Below are two different circuits. In the first, every time you switch off the ignition the alarm will turn itself on - and every time you switch on the ignition the alarm will turn itself off. The second circuit works in the same way - but with the added security provided by Sw1. The ignition key alone will not turn the alarm off. You need to push Sw1 before the relay will energize.

Whichever circuit you use, the relay will only be energized while the ignition is on. When the bike is parked and the alarm is on, the relay coil is not using any current. So there is no drain on the battery.

Depending on the circuit, you'll need a single or double-pole relay with a contact rating of at least 1-amp. When you have it all wired-up correctly, protect it from the elements by wrapping it well with several layers of electrical tape.

Add an Immobilizer to the Machine

Before fitting this or any other immobilizer to your bike, carefully consider both the safety implications of its possible failure - and the legal consequences of installing a device that could cause an accident. If you decide to proceed - you will need to use the highest standards of materials and workmanship.

Remember that the relay must be suitable for the current it's required to carry. Choose one specifically designed for automobiles - it will be protected against the elements and will give the best long-term reliability. You don't want it to let you down on a cold wet night - or worse still - in fast moving traffic!!!

Please note that I am UNABLE to help any further with either the choice of a suitable relay - or with advice on its installation.