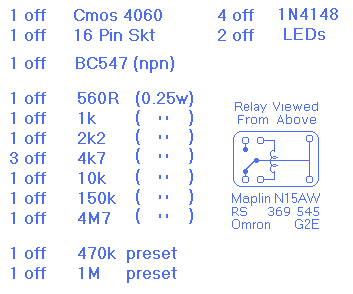

The components used in the circuit should be widely available. However, none of them are critical. So - if you can't find the specified parts -

You're certain to find something that will do just as well.

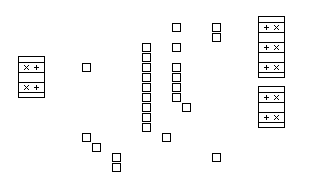

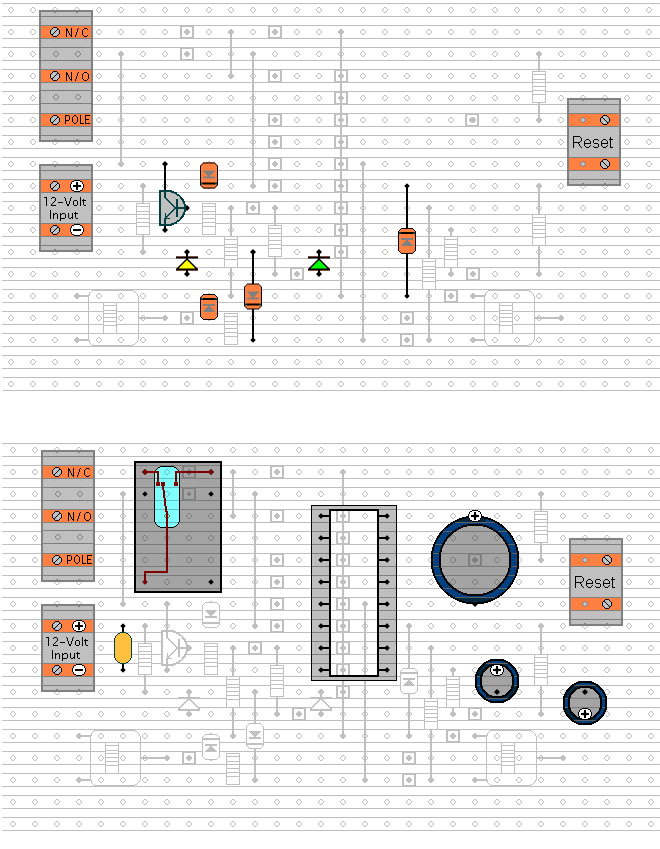

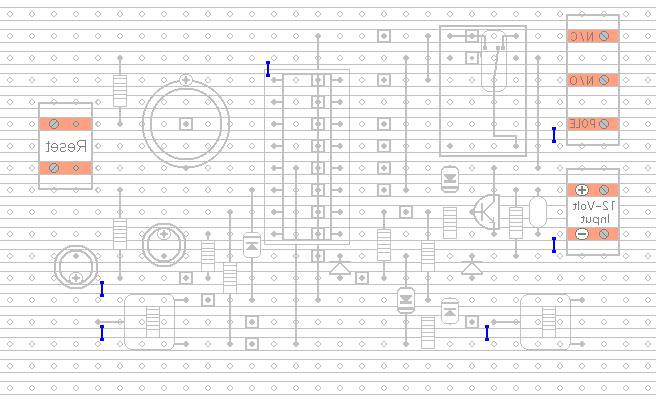

Stripboard or Veroboard is a board drilled with a matrix of 1mm holes spaced approximately 2.5 mm apart and joined in rows by copper strips. The piece used for the prototype has 18 rows with 30 holes in each - and measures about 7.5 cm by 5 cm (3" by 2"). The drawing shows the board with PCB mounting terminal blocks. But to save money and/or space - you can use veropins instead. Or you could simply solder the wires directly to the board itself.

Parts List

Click Here For A Photograph Of The Prototype.

Construction Notes

Click here if you're new to constructing stripboard projects.

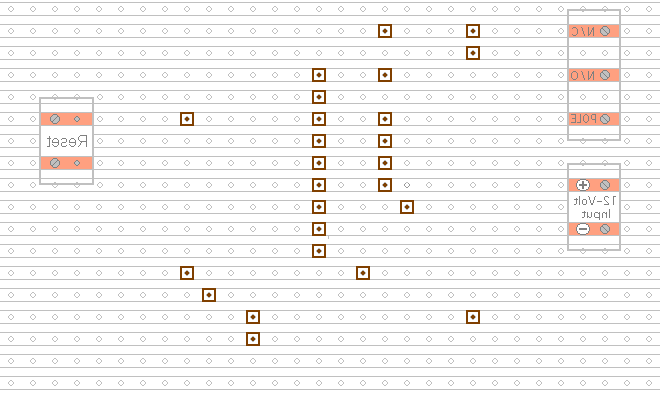

The terminals are a good set of reference points. To fit them, you may need to

enlarge the holes slightly. Then turn the board over and use a felt-tip pen to

mark the 25 places where the tracks are to be cut. Use the "actual size" drawing

to

Check That The Pattern is Correctly Marked .

Actual Size

When you're satisfied that the pattern is right - cut the tracks. Make sure that the copper is cut all the way through. Sometimes a small strand of copper remains at the side of the cut and this will cause malfunction. Use a magnifying glass - and backlight the board. It only takes the smallest strand of copper to cause a problem. If you don't have the proper track-cutting tool - a 6 to 8mm drill-bit will do. Just use the drill-bit as a hand tool - there's no need for a drilling machine.

Next - make and fit the

Five Wire Links. For the links - I used bare copper wire on the component side of the board. Telephone cable is suitable - the single stranded variety used indoors to wire telephone sockets. Stretching the core slightly will straighten it - and also allow the insulation to slip off.

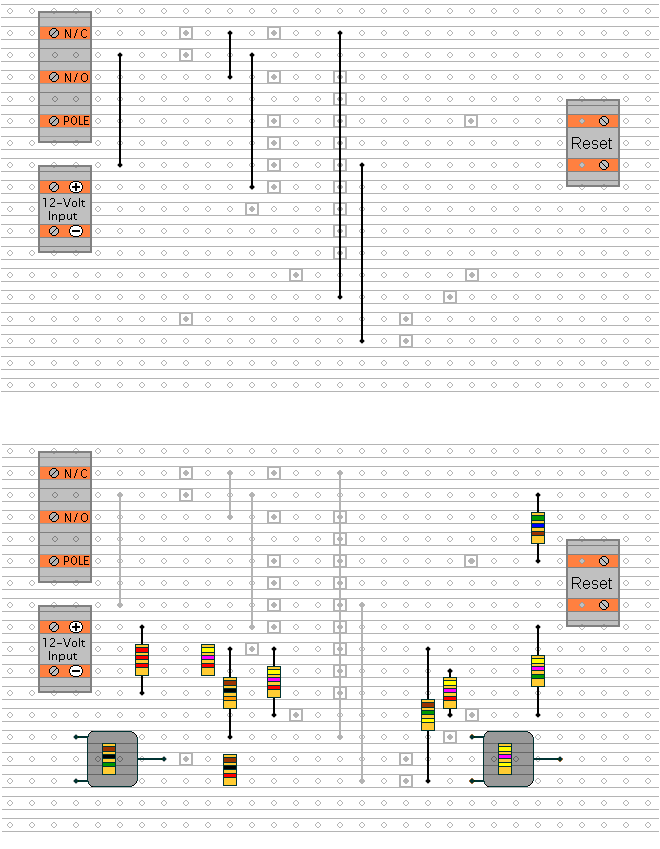

Next fit the nine fixed resistors - and the 2 presets. To fit the presets you may need to enlarge the holes slightly. All the fixed resistors are drawn lying flat on the board. However, those connected between close or adjacent tracks are mounted standing upright. See the

Photo Of The Prototype.

The next stage is to fit the diodes - the transistor and the LEDs. Pay particular attention to the orientation of each and every component. Note that two of the 1N4148 diodes are facing up - and the other two are facing down.

Fit the remaining components - the four capacitors - the IC socket - and the relay. Pay particular attention to the orientation of the electrolytic capacitors. They generally have a stripe down the side next to the

Negative terminal. Note that the two 22uF capacitors are mounted with their positive terminals facing in opposite directions. See the

Photo Of The Prototype.

Turn the board over and examine the underside carefully - to make sure that there are no unwanted solder bridges or other connections between the tracks. If you backlight the board during the examination - it makes potential problem areas easier to spot. When you're satisfied that everything is in order - add the six (blue) solder bridges. These are just small blobs of solder - used to connect adjacent copper tracks.

Finish off by inserting the Cmos 4060 into the socket. Pin 1 of the IC should be in the top left-hand corner. Check that all 16 pins have entered the socket. Sometimes - instead of entering the socket - a pin will curl up under the IC.

You Are Now Ready To Test Your Circuit