How to convert a stripboard layout into a printed circuit board.

A Much Simpler Project

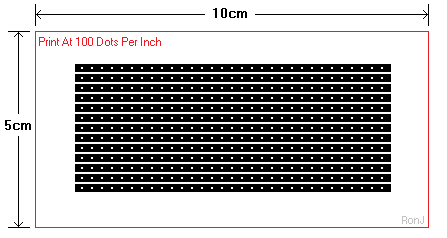

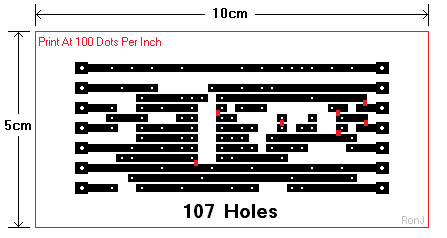

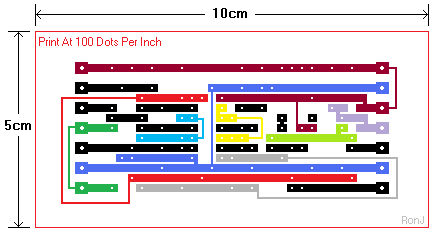

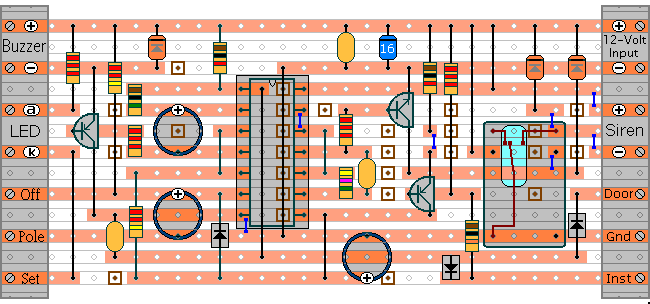

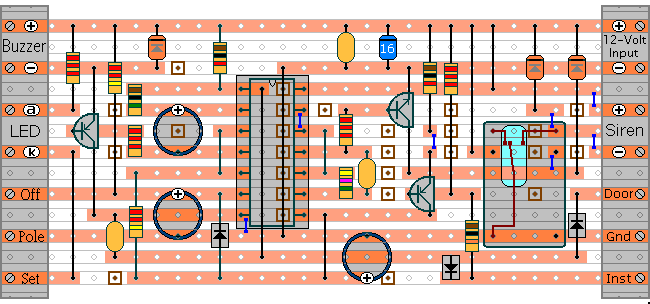

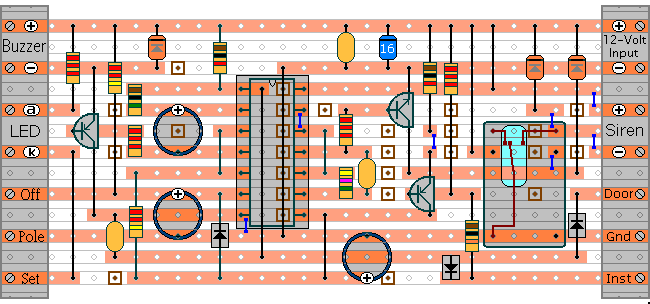

I've used my Car Alarm Circuit to illustrate the conversion process. But the technique can be applied to any stripboard layout. Begin by saving a copy of the Stripboard Template. It's designed to be printed at 100 dpi. Note that this print resolution must be maintained. Otherwise - the resulting PCB - will be the wrong size.

All the work on the template is done from the component side. The resulting drawing will be flipped horizontally before use. Open the template with Paint. Mark off the section of the stripboard you need - and delete the rest. How far you take the process after that - depends on the degree of refinement you want.

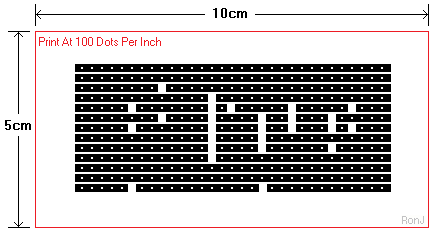

You could simply print the section of board - with all the strips intact. Or you could take the opportunity to sever the tracks where required. This can be done - quite conveniently - using the square "Eraser" tool. If you make a mistake - click on "Edit" - and select "Undo".

Unused sections of track can be neatly removed - using the rectangular "Select" tool - followed by the keyboard's "Delete" key. If you make a mistake - use "Edit" and "Undo". The solder bridges can be added using the "Line" tool. I made them wider by selecting one of the broader line options. I coloured them red - to make them visible. You'll make your solder bridges black.

The broad line will also blank out the unused holes. If you hold down the "Shift" key as you draw - the line will be straight. You can check your work by calculating the total number of component leads, wire links and terminals the board has to accommodate. When I'd finished - the correct number of holes remained. So I was fairly certain that the pattern was right.

Finally - I used the "Pencil" tool to make the terminal holes larger - and increase the area of the solder pads. You only have to draw one pad. Then "Copy" it once - and use "Paste" to create all the rest.

Replacing The Wire Links

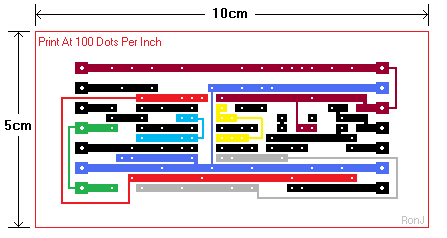

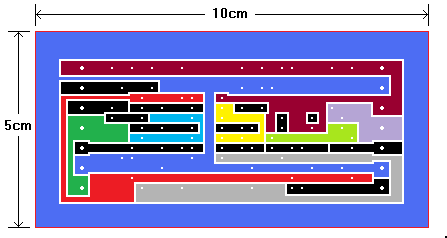

Each link joins a pair of tracks. Use the "Fill" tool to make each pair of tracks the same colour. Then look for suitable routes to link the pairs together. When you've done - the "Fill" tool can be used to make the tracks black again.

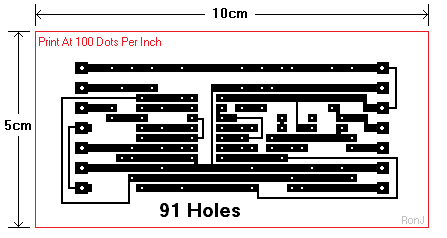

When I replaced the eight wire links - a further 16 holes became redundant. When I blanked them out - 91 holes remained. Replacing the links also made some areas of track redundant. For example - the green tracks at the bottom left of the drawing. I removed them with the "Eraser" tool. You can use "Edit" and "Undo" to correct any mistakes.

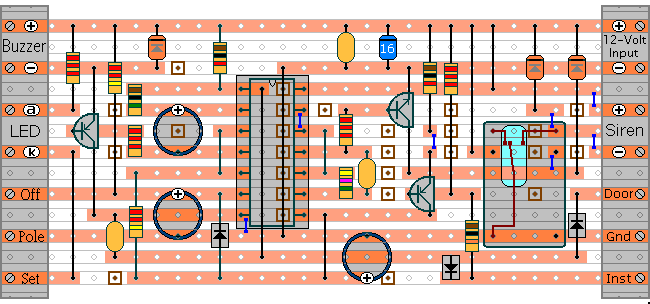

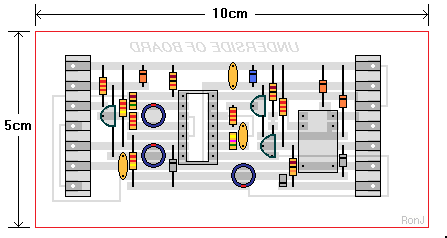

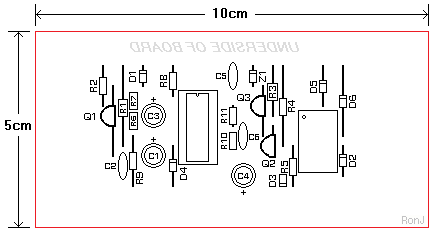

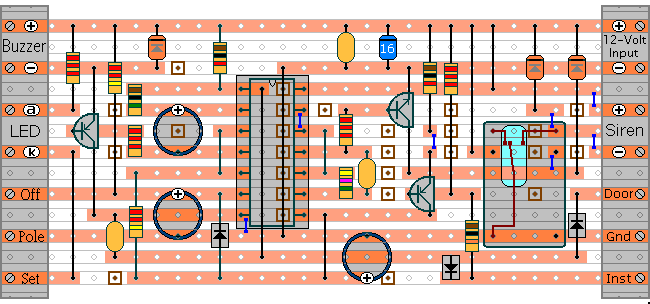

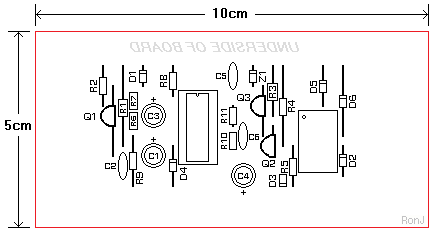

To check your work - make a copy of the board with pale grey tracks - and add the components to the drawing. You can do this by hand - with pencil and paper. Or you can do it with Paint - as a prelude to producing a component overlay.

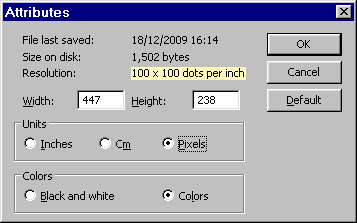

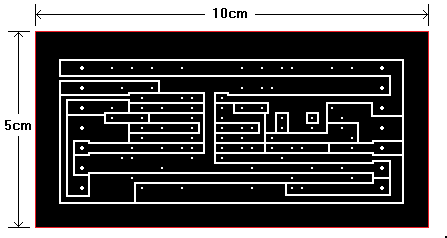

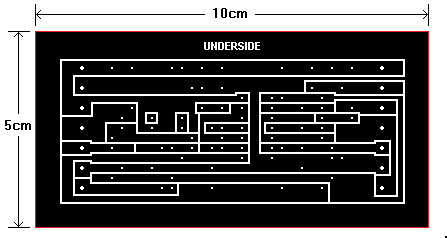

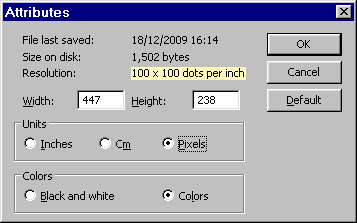

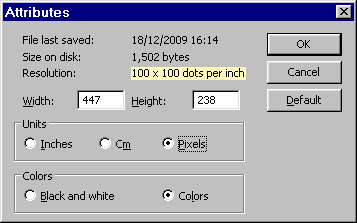

Finally - flip the drawing horizontally. Click on "Image"---"Flip/Rotate"---"Ok". Then add whatever text or other items you want - to the underside of the board. Before you make your board - check that your drawing will print at 100 dpi. Click "Image" - then "Attributes" - and check the resolution.

If the print resolution has changed - it can be restored to 100 dpi using one of the techniques described at the bottom of the Stripboard Template Page.

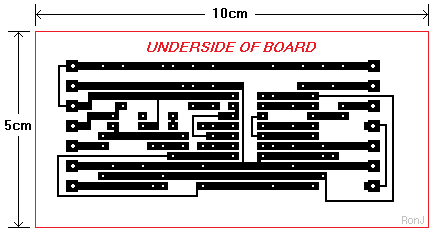

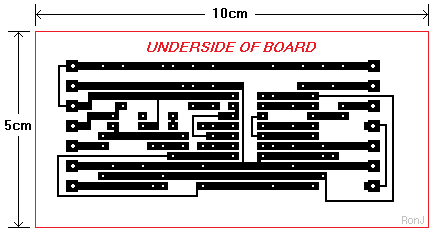

Car Alarm - Finished PCB

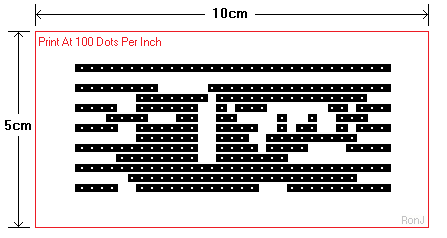

Note that the red box is not the edge of the board. It's just there to help confirm that the printout is the right size. The pattern must be printed at a resolution of 100 dots per inch. But the actual outside dimensions of the board are entirely up to you.

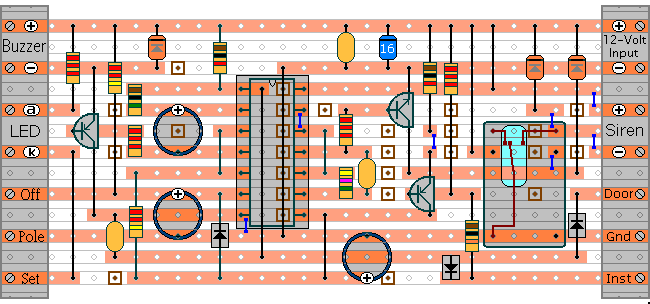

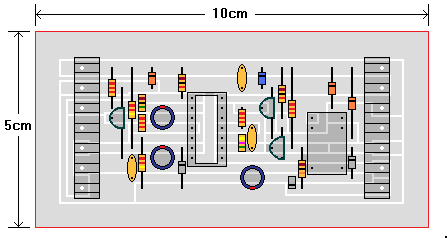

Reduce The Area To Be Etched

There is no point in removing more copper than you have to. With a simple circuit like this one - the strips can easily be converted into large pads. Use the "Fill" tool to make the various groups of tracks - different colours. Then use the "Line" tool and the "Fill" tool to expand the various groups into pads. There's no single correct pattern. You can make the pads any shape you like.

When you're satisfied with your work - flip the drawing horizontally. Click on "Image"- then "Flip/Rotate" and "Ok". At this stage - it's worthwhile adding a word such as "Underside" - to avoid any future confusion.

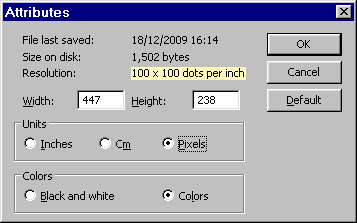

Before you actually make your print - check that the resolution hasn't changed. Click on "Image" - and then "Attributes". The resolution should read "100 x 100 dots per inch". If it has changed - it can be restored to 100 dpi by using one of the techniques described at the bottom of the Stripboard Template Page.

Component Overlay

To check your work - make a copy of the board with pale grey pads - and add the components to the drawing. You can do this by hand - with pencil and paper. Or you can do it with Paint - as a prelude to producing a component overlay.

Car Alarm Circuit

SUGGESTIONS

SUGGESTIONS

SUGGESTIONS

SUGGESTIONS