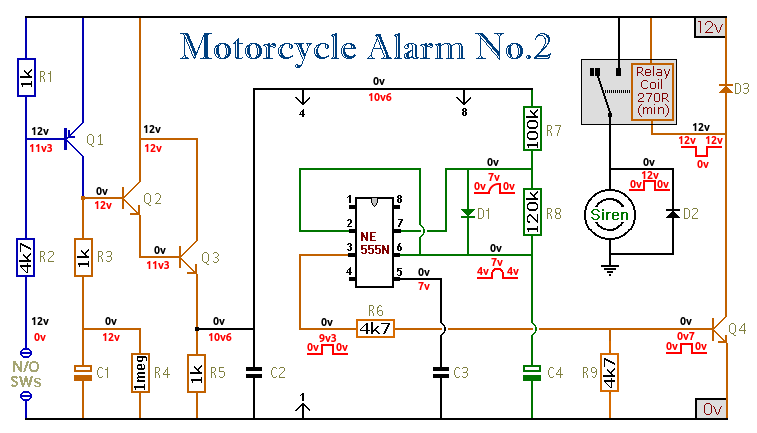

Build this simple motorcycle alarm circuit yourself using veroboard - a 555 timer - and a few cheap off-the-shelf components. In standby mode it uses no current - so it won't drain your motorcycle battery.

Introduction

The prototype of this Motorcycle Alarm was built using only the Stripboard Layout as a guide. So - if you have faithfully reproduced that layout - you will have a working circuit.

Once you're satisfied that your layout is correct - and you have made a careful and thorough check of the underside of the board - it's time to power-up the circuit and test its operation. This is always an anxious moment. If you construct a lot of circuits - you might consider building the Current Limiting Power Supply - or alternatively - you could add the Simple Current Limiter to your existing PSU. Both will let you set an upper limit on the amount of current supplied to your circuit - and so protect it from any serious damage. Setup

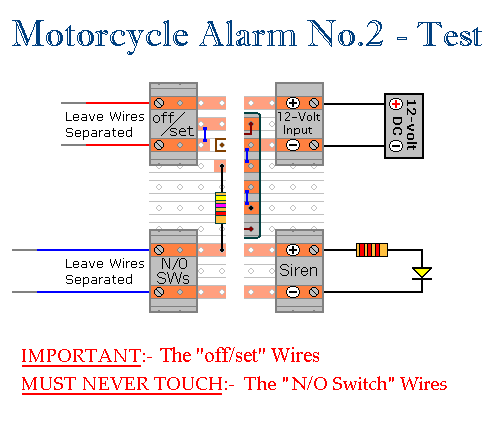

A resistor and an LED are all that's needed to demonstrate that the "Siren" output is working properly - and you can simulate the switches using four lengths of wire.

Because the "Off/Set" switch terminals are connected to the positive line, and the "N/O" switch terminals are connected to the negative line - it's IMPORTANT that the wires should never come in contact with each other. So make the pairs different colours - and different lengths.

|