If - in the course of the test - you find that something is not working properly, then a careful inspection of the relevant area of the circuit board should turn up the cause of the problem. If the LED is not lighting - check that it's connected the right way round. Where you've cut the board to size - look for small loose strands of copper left behind by the saw. Check the board for short-circuits caused by component leads touching each other. It can also happen that the stripboard itself is faulty. I have seen cases where the copper tracks have not been completely severed from one another during manufacture.

If you've built your circuit using the specified components - and you've followed the step-by-step construction guide described on the

Support Page - then the chances are that any bug will be caused by something minor - a component connected the wrong way round - a missing or unwanted solder bridge - an incomplete cut in the track etc.

If you can't see anything obvious then adopt a systematic approach to faultfinding. Begin by double-checking that all of the cuts in the tracks have been made, that they are all -

In The Right Place - and that they sever the track completely. Use a magnifying glass - and backlight the board. It only takes the smallest strand of copper to cause a problem.

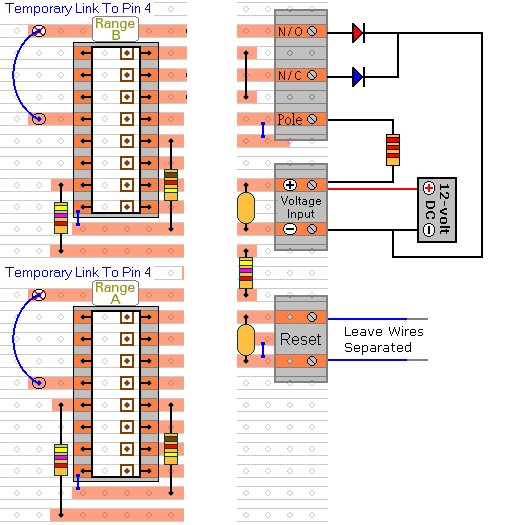

When you're satisfied that the tracks have been severed in all the right places, check that you have made - and correctly placed - all six solder bridges. Mark each bridge with a felt-tip pen - or something similar - so that it can be easily identified later.

Next, carefully examine the full length of each track. If you backlight the board during the examination - it makes potential problem areas easier to spot. Look for unwanted solder bridges. Your felt-tip markings will tell you which ones should be there - and help you to identify any that shouldn't be there.

If all else fails and you still haven't found the cause of the problem - work your way through the assembly instructions on the

Support Page. Check each individual component and link - to make sure that it's present and correctly positioned.

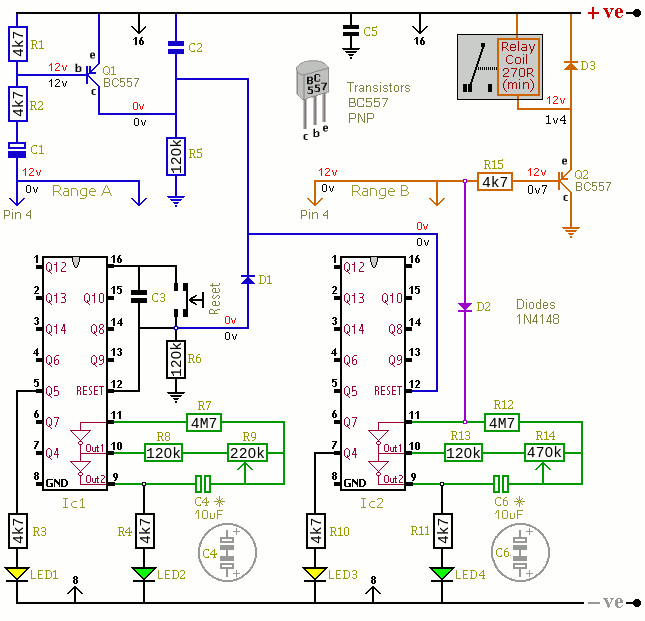

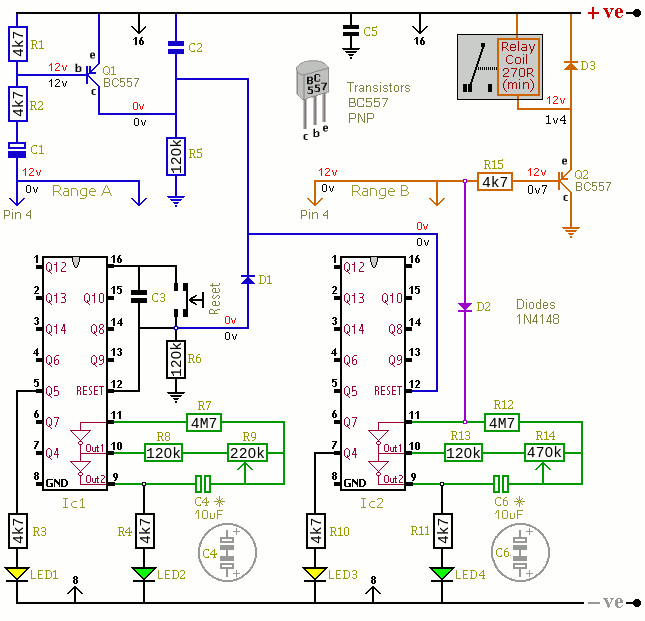

Print out the drawings and mark off the components as you go. Take your time and examine each individual component carefully. Pay particular attention to the orientation of the diodes, transistors and electrolytic capacitors. Make sure that both transistors are PNP. Check that the Q1 emitter is connected to the positive line. And check that the Q2 collector is connected to the negative line.

If You Haven't Followed The Construction Guide

You may want to try the circuit out on a

Breadboard first. Or you may want to design your own PCB - rather than use the stripboard layout I've provided. Perhaps you've had to use components that are different from those I've specified. If you're having problems and need my help - please tell me exactly what you're trying to do. Otherwise I'll assume that you're following my construction guide. And that may cause confusion.

A common fault with breadboards is an error in the power connections. Your breadboard is likely to have several separate power strips (positive and negative). And you may be using more than one of each. So make sure that all of the power strips you're using - are actually connected to the supply.

The circuit uses tried and tested components and techniques. It should work perfectly every time. If it's not working - the most likely cause is an error in your layout and/or your connections. The most common error is caused by pin configuration. Are you really certain that you've connected your relay and transistors correctly?

Fault-Finding Guide

Begin by making absolutely certain that pin 16 of each 4060 is connected to the positive power terminal. And that pin 8 is connected to the negative power terminal.

If a green LED is not flashing - check that it's connected the right way round. If it is connected the right way round - then the oscillator is not running. In the case of Ic2 - try removing D2 temporarily.

You should be able to get both oscillators to run - regardless of what's happening elsewhere in the circuit. Carefully check the components and connections associated with pins 9, 10, 11 & 12.

After eight flashes of the upper green LED - the upper yellow LED should light. And it should turn off again after a further eight flashes.

Similarly - after sixteen flashes of the lower green LED - the lower yellow LED should light. And it should turn off again after a further sixteen flashes.

If the oscillator is running and pins 8, 12 & 16 are correctly connected - the yellow LED should be switching on and off as described. If it's not - the 4060 is probably faulty.

When the upper yellow LED switches off for the second time - pin 4 of Ic2 should go high - and the oscillator should stop with its green LED lit.

If your relay does not change state when pin 4 of Ic2 goes high - there's something wrong with the (orange) output stage.

To test the relay section separately - disconnect the range wire from pin 4 of Ic2. When you touch the loose end of the range wire to the negative power terminal - the relay should energize.

If you haven't used the specified transistors - make sure that the ones you have used are PNP. And - check the Pin Configuration. Just because they look the same as a BC557 - don't assume that the pins are arranged in the same order.

If you haven't used the specified relay - make sure that your relay has the same Pin Configuration. Just because it looks the same - and fits into the layout - don't assume that its internal connections are arranged in the same pattern.

Below are some voltage readings you may find helpful. The figures in black are roughly what you should get when pin 4 is low. And those in red are what you should get when pin 4 is high. If you've used a 9v supply - then for 12v read 9v.

Voltage Readings